How Does a 3D Printed Knee Replacement Work?

Medical professionals now use 3D printing to create titanium jaws, hearing aids, limbs, organs, and in the production of customized knee replacements.

Invented by Chuck Hull back in 1983, 3D printing is the process of using a printer to transform a digital three-dimensional model into a physical object. Learn how a 3D printed knee replacement works and how Conformis can transform a digital three-dimensional model into a physical object.

Additive Manufacturing

There are two basic types of manufacturing: subtractive and additive. In subtractive manufacturing, manufacturers start with a large block of material then shave away, or subtract, what they do not need.

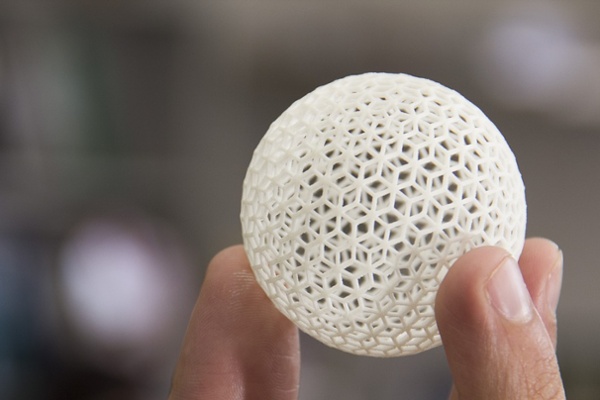

Additive manufacturing is the direct opposite of subtractive manufacturing – manufacturers add layer upon layer of material to achieve the desired effect. 3D printing is additive manufacturing, as special print heads lay down layers of various materials to create products.

While subtractive processes have been the mainstay of manufacturing for decades and are still the norm, 3D printing and other additive manufacturing processes have distinct benefits. Subtractive manufacturing requires stripping away material, creating a great amount of waste, to make each component of a piece then assembling all the components to create the finished product. 3D printing allows manufacturers to create very complex products containing multiple materials with very little waste.

A 3D printed knee replacement consists of:

- Nylon

- ABS plastic

- Resin

- Stainless steel

- Gold and silver

- Titanium

- Ceramic

- Gypsum

The ability to use a variety of materials allows manufacturers to make incredibly strong and complex items. Many of the materials, especially titanium, are suitable for use in medical devices because of their strength and lower risk for rejection. By building objects up in layers, 3D printing can produce objects that are hollow or extremely intricate.

3D Printed Knee Replacement: What We Print and Why

At Conformis, we use the latest in 3D printing (additive manufacturing) technology to create one set of surgical instrumentation, called iJigs, per patient. These instruments allow your surgeon to ensure that your customized implant is positioned correctly.

To create the iJigs, a robotic arm deposits a layer of powdered nylon onto a tray. A laser then outlines each patient-specific shape, fusing the powder into solid shapes. This process is repeated many times, until the layers have built up and the final shapes of the instruments are created. When the jigs are removed from the 3D printer, they are consolidated in one rectangular package. The individual pieces are then removed and sterilized before being packaged for shipment to your surgeon. We also use 3D printing to create the wax molds the metal implants are cast in.

Once the stuff of science fiction novels, 3D printing is now revolutionizing medicine.

Related Posts